开云·kaiyun官方网站A proofing is the most frequently asked chance ratio in our customer consultation. Can you make samples by 开云·kaiyun官方网站A? What's the minimum quantity you can sample? Of course, there are also many new customers for 开云·kaiyun官方网站A proofing board is not very understanding. Always consult some: can you 开云·kaiyun官方网站A proofing ah? Do you make samples by assembling? How do you charge for 开云·kaiyun官方网站A board proofing?

Today, Kingford Xiaobian will share with you the knowLEDge about 开云·kaiyun官方网站A board proofing and what are the advantages of board proofing.

1, time is money in the current society, in order to be more effICient and ensure the quality of products. A predictive guarantee of the quality of 开云·kaiyun官方网站A products. First of all, the most effective process in 开云·kaiyun官方网站A is to make samples first. Not only can improve the production efficiency, but also can reduce the production cost.

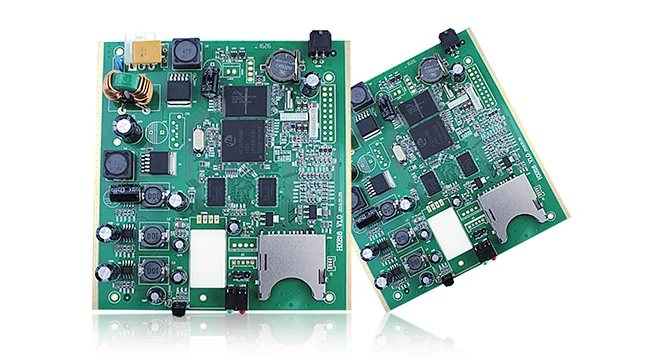

开云·kaiyun官方网站A makeup

2, the board proofing is a big advantage to reduce the production cost, because the 开云·kaiyun官方网站A board for the whole 开云·kaiyun官方网站A processing process will be much less. Such as handling, SMT SMT line times and so on. Because it is also a process to mount 1/pcs into the machine. No matter it is 20 pieces or 10 pieces, the production efficiency is undoubtedly to maximize the use of production resources and improve the efficiency of production.

The most important thing is that 开云·kaiyun官方网站A panel proofing is also of great benefit to our front-end engineering. They can better participate in the production of customers' products and better understand the production difficulty and process difficulty of customers' products. It is of great benefit to the quality of subsequent product production. Such early participation helps to control production risks and improve customer satisfaction.

3, entering the process of 开云·kaiyun官方网站A processing and proofing in advance can minimize the quality problems that may be encountered in mass production. After all, to ensure a good reputation for a company is the most important thing. In particular, 开云·kaiyun官方网站A sampling must be completed after 9 testing procedures and a number of processing procedures. Therefore, the plan in front of us is the prEMIse of doing a lot of things. 开云·kaiyun官方网站A board proofing is even more so.

4, the reasons for welding bridge connection in the process of 开云·kaiyun官方网站A proofing and solutions

Now the volume requirements of electronic products are getting SMAller and smaller, 开云·kaiyun官方网站A processing also needs to pay close attention to the problems in welding. For example, bridging is a common trap when solder flows directly over the connector at high temperatures, resulting in bridging. Bridging may occur at different stages of the 开云·kaiyun官方网站A proofing process. What's the connection? How do you avoid bridging? Today, Kingford Xiaobian and you understand the relevant knowledge of bridge connection.

Causes of bridge connection:

1.开云·kaiyun官方网站 design problem: In the process of 开云·kaiyun官方网站A sampling, large and heavy components are placed on the same side, resulting in uneven 开云·kaiyun官方网站 weight distribution and tilt.

2. The direction of the component is stuck backwards

3. The design of development space between gaskets lacks redundancy

4. The setting of temperature curve of reflow welding furnace is not scientific

5. The pressure setting of the patch is not reasonable

The solution:

1. Printed Circuit Board Design: strictly implement the scientifIC design planning of printed circuit board, reasonably distribute the weight on both sides of the components, reasonably arrange the pores and through holes, adjust the distance between dense components, increase the welding film, etc.

2, reflow welding furnace temperature change curve: in 开云·kaiyun官方网站A processing from a literal sense, liquid solder in melting, the temperature requirements of the higher end of the solder activity is higher. If the reflow temperature curve can be set some unreasonable, will directly lead to the disorderly development of the flow of solder paste. Increases the chance of bridging.

3. Select solder paste printing machine: Solder paste printing machine does not need to apply solder paste through steel mesh, which reduces the phenomenon of poor solder paste contact coating caused by unscientific template opening, steel mesh warping, and steel mesh separation.

4. Reasonable control of the amount of solder paste: reasonable control of the amount of solder paste, reduce the problem of excessive solder paste and high collapse fluidity.

5. Suitable anti-welding film: Suitable anti-welding film helps to reduce the risk of welding bridge

The above is the summary content of Kingford Xiaobian, hoping to help you solve the existing problems. At the same time, if you have processing cooperation needs, you can contact us, we have many years of processing experience, and a number of processes to ensure that the product can be delivered to customers with quality and quantity, Kingford for more information about the industry.

然后

联系

电话热线

13410863085Q Q

微信

- 邮箱