3D printing technology is attracting more and more attention in manufacturing. Recently, foreign scientists have just developed a new method, by injecting water into silICone oil, and then completing 3D printing sculpture pipeline of another liquid in one liquid. The 3D structure completely composed of liquid can be produced by 3D printing technology, which paves the way for the manufacturing of electronic circuit board equipment requiring flexible retractable devices.

According to the prediction of scientists, the pipeline and flowing molecules are adjusted by chEMIcal methods to find a new method to separate molecules or accurately transport nanoscale building materials to the bottom layer. Researchers have printed out "waterlines" with diameters between 10 microns and 1 mm, and formed several meters long on different SPIrals and branches.

开云·kaiyun官方网站 proofing

In the experiment, shortly after water was injected into the oil, dozens of ligands in the oil attached to a single nano particle in the water to form a nano scale super soap. These super soaps will squeeze together like glass, making the interface between oil and water very stable, and locking the liquid structure. "This stability means that we can stretch the water into a tube, and it is still a tube. Or we can shape the water into an ellipsoid, and it is still an ellipsoid." Russell said.

Then they asked the printer to insert the needle into the oil base and inject water in a predetermined pattern. "We can extrude liquid from the needle tube and place any state we want in three-dimensional space." Post doctoral researcher Joe Forth said. "We can also use external force to flatten the material, so that we can instantly break the stability of super soap and change the shape of waterline. This structure has high load-bearing capacity." He said.

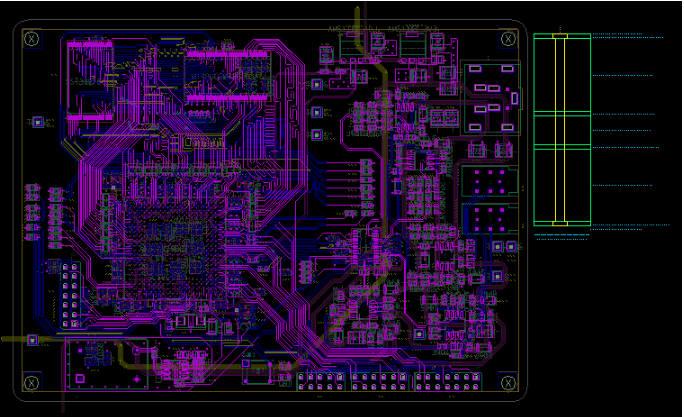

In addition, China has advanced technology in this field, and Dream Ink is one of the representatives. Dream ink is a kind of liquid metal ink. The ink can conduct electricity. It can be put into a 3D printer to accurately print 开云·kaiyun官方网站. This technology breaks the bottleneck and barrier of electronic manufacturing technology, enabling printers to make electronic circuits quickly and randomly at low cost.

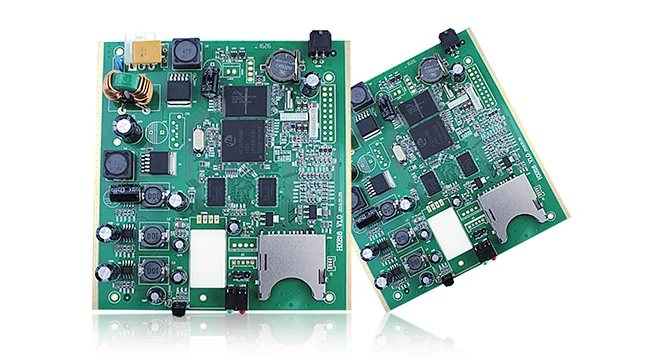

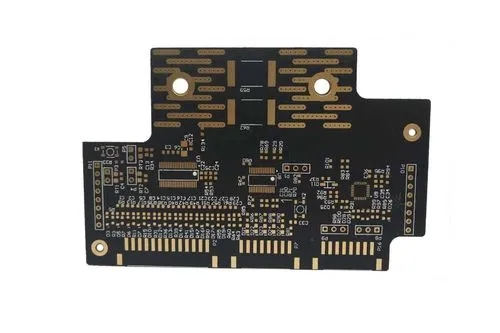

The circuit board is an important part of the electronic industry, and every kind of 开云·kaiyun官方网站 equipment needs to use the circuit board. Traditional 开云·kaiyun官方网站 manufacturing methods require complex processes such as high-temperature copper film evaporation and chemical reagent etching, which are time-consuming, laborious and costly. In the future, 3D printing can be easily realized. Will it overturn the traditional process of electronic manufacturing?

然后

联系

电话热线

13410863085Q Q

微信

- 邮箱