The thermal imaging circuit board fault test, circuit board fault detector is specifICally designed for circuit board and electronic failure analysis, using infrared imaging technology, can quickly detect the location of defects, thereby reducing the time and cost of detection for the majority of users, and also reduce waste generation. In addition, this set of circuit board 开云·kaiyun官方网站A failure analysis instrument,开云·kaiyun官方网站A failure detection instrument can also detect the basic function of the circuit board, compared with the traditional professional circuit board detection means, this set of 开云·kaiyun官方网站A failure testing instrument, the price of 开云·kaiyun官方网站A fault testing instrument is lower,开云·kaiyun官方网站A short circuit tester,开云·kaiyun官方网站A defect analyzer is more convenient to use, The effect is more intuitive. 开云·kaiyun官方网站A bad tester,开云·kaiyun官方网站 bad detector,开云·kaiyun官方网站A short circuit tester can be widely used for power supply to ground short circuit maintenance, inner short circuit maintenance,BGA short circuit maintenance, Transistor short-circuit maintenance, diode short-circuit maintenance, inductor short-circuit maintenance, decoupling capacitor short-circuit maintenance, electronIC components internal short-circuit, resistance short-circuit, solid poor inspection, circuit board maintenance, printed circuit board, failure analysis, infrared imaging, thermal imaging maintenance, circuit board short-circuit inspection.

Main Applications

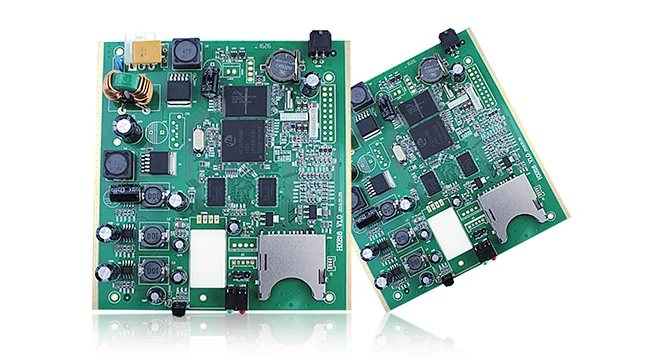

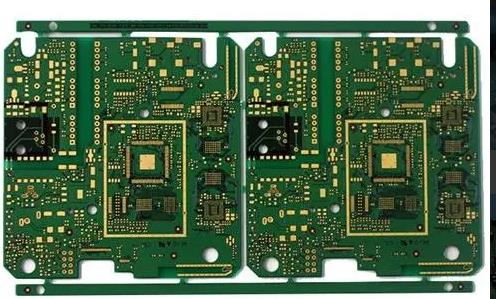

Circuit board fault test, circuit board fault detector quickly determine the location of short circuit and extruded components, including: power to ground short circuit, inner short circuit, BGA short circuit, transistor short circuit, diode short circuit, inductor short circuit, decoupling capacitor short circuit, electronic components internal short circuit, resistance short circuit, poor solid.

开云·kaiyun官方网站A failure analysis,开云·kaiyun官方网站A failure detection,开云·kaiyun官方网站A failure test to verify circuit board function;

开云·kaiyun官方网站A fault test,开云·kaiyun官方网站A short-circuit test,开云·kaiyun官方网站A bad analysis analysis of the thermal performance of each component;

开云·kaiyun官方网站A bad test,开云·kaiyun官方网站 bad test,开云·kaiyun官方网站A short circuit test evaluation of thermal management components

We use a highly sensitive thermal imaging CAMera, combined with powerful noise subtraction and image enhancement software, to provide you with a tool to quickly locate the problem, identify the problem within seconds, detect abnormalities in power consumption as SMAll as 1 milliwatt, and detect temperature increases of 0.03 degrees Celsius.

During the test, the 开云·kaiyun官方网站 board can be energized for 5-10 seconds to start the test work. The I/0 module can automatically control the power input to the circuit board. After the circuit board is energized, the heat will dissipate in the short circuit part. This set of 开云·kaiyun官方网站A failure analysis,开云·kaiyun官方网站A failure detection,开云·kaiyun官方网站 failure analyzer will easily capture the temperature rise, so as to find the short circuit location. A short circuit with high resistance (greater than 10 ohms) causes a temperature rise of at least 1 degree Celsius and is not difficult to detect. However, for low resistance short circuits, such as 0.5 ohms, the resulting temperature increase is very weak, perhaps as little as 0.2 degrees Celsius, and such short circuits are very difficult to detect. However, our printed circuit board failure analyzer and printed circuit board failure finder have the functions of "noise deduction and image enhancement" in the software. When the detection system works in this mode, when the circuit board is not powered on, the system will collect a thermal image for reference. After the circuit board is powered on, a series of thermal images of the circuit board will be collected. These images will be processed by subtracting the "reference image", so that a very weak temperature change after the circuit board is energized can be obtained, even for a temperature change of 0.03 degrees Celsius, the 开云·kaiyun官方网站 short circuit detector, the 开云·kaiyun官方网站 short circuit locator can find the short circuit location. The software's transparent image overlay function helps you detect defects with resistance as low as 1 ohms. Small resistance notch is where there is a thermal problem. It takes less power to quickly find the location of the defect. The software can also automatically cut off the circuit board's power supply to protect it from damage

然后

联系

电话热线

13410863085Q Q

微信

- 邮箱