What is AOI automatIC optical detector?

The circuit board manufacturer and circuit board designer will explain to you what the AOI automatic optical detector is

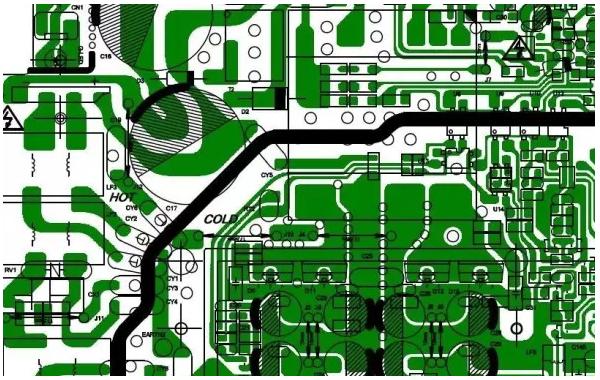

AOI (Automatic Optical Inspection) is an automatic optical inspection, a new emerging testing technology, and a device based on optical principles to detect common defects encountered in welding production. AOI uses rich special multi-function detection algorithms and binary or gray level optical imaging processing technology for detection.

AOI (Automatic Optical Inspection) is an automatic optical inspection, a new emerging testing technology, and a device based on optical principles to detect common defects encountered in welding production. AOI uses rich special multi-function detection algorithms and binary or gray level optical imaging processing technology for detection. Although AOI can be used at multiple locations on the production line, each location can detect special defects, AOI inspection equipment should be placed at a location where the most defects can be identified and corrected as early as possible. AOI is usually placed at the end of the production line, where equipment can generate a wide range of process control information.

AOI checkers must and can handle the problems caused by different changes. By using AOI as a tool to reduce defects, errors can be found and eliminated early in the assembly process to achieve good process control. Early detection of defects can avoid sending the bad board to the subsequent assembly stage.

开云·kaiyun官方网站A factory uses inspection equipment to monitor the production process. Typically, it includes detaiLED defect classification and component placement offset information. When product reliability is important, mass manufacturing with low mixing degree, and component supply is stable, manufacturers give priority to this goal. This often requires that the inspection equipment be placed at several positions on the production line to monitor the specific production conditions online and provide necessary basis for the adjustment of the production process.

AOI software has a comprehensive verification function, which can reduce false positives of inspection and ensure that the inspection program is free of defects. It can check defective samples stored, such as samples stored in repair stations, and blank printed circuit boards printed with solder paste. In the optimization phase, the reason for spending time in this area is to prevent any defects from slipping past. All known defects must be checked, and the number of false positives allowed shall be minimized. When adjusting any procedure to reduce false positives, check to see if the straight defects previously detected have been confirmed by the maintenance station. Through comprehensive verification, the quality of inspection procedures shall be guaranteed for special manufacturing and verification, and false positives shall be tracked.

然后

联系

电话热线

13410863085Q Q

微信

- 邮箱